Future built on experience - for almost 100 years

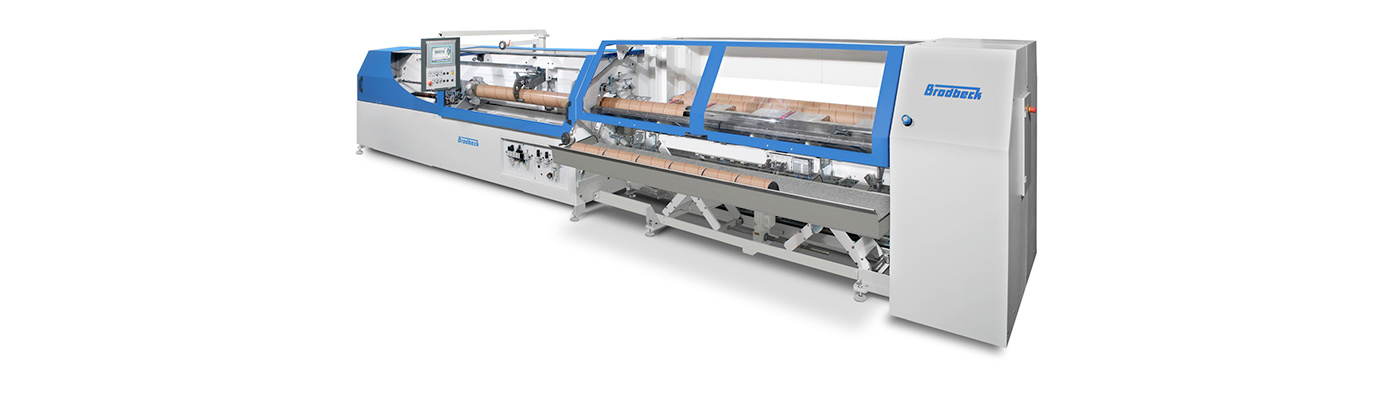

Core and tube cutters from Brodbeck

Whether you need to wind, finish or cut cores or tubes made of paper, cardboard or plastic: you have come to the right address at Brodbeck GmbH.

As the technology leader in our field, we have specialized in the manufacture of high-end machines and customized plants for core, tube and film manufacturers, printers and paper producers.

Also part of our range: machines for convolute wound tubes used in the textile industry.

News

New Year, New Construction Site!

At Brodbeck, we’re kicking off the year with another exciting improvement in our production and assembly hall.